This is going to be a long reply... it's a brain dump so excuse the long windedness of some sections. I suggest you also watch the brew in a bag youtube videos I shared in an earlier post which describes all of this.

Mashing

The programme shown above is for automated (and expensive) brewing equipment. I suggest using a thermometer bring your strike water up to boil and check that it is around 78°C to 80°C; which is slightly higher than the grain steeping temperature of 73°C -- the reason is that the malt grains will be cooler and adding them will drop the temperature to hopefully 73°C.

For the entire mash cycle you want to maintain the 73°C without having the pot on the stove as that could end up burning the bottom; you want to heat up the strike water to the temperature of 73°C and the turn off the heat. I wrap my brew pot in a thermal blanket to maintain the heat during the mash cycle; a blanket or towel should also work.

You can also get plastic fermenters that are double walled similar to beer coolers; which maintain the heat just as well as the cold.

Only challenge with these is that you have to transfer you wort after the mash to a brew pot for the boil and then back again after the boil. I use standard food grade 20 litre plastic buckets fitted with an airlock and tap for the fermenters, and I use a 30litre stainless steel brew pot for the mash cycle and the boil; I transfer the wort to the fermenter buckets after the boil.

For the strike water i.e. hot water; that is used for the sparging before the boil.

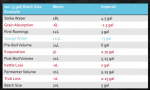

Calculating the amount of strike water you'll need is important; here's an example:

View attachment 1285

Let's walk through this.

You work essentially backward on this table, with the batch size being what wort volume your recipe is designed to produce.

The trub is the bottom sediment layer (which includes yeast and proteins) that forms at the bottom of your fermenter; naturally we don't bottle that. the fermenter volume will be slightly higher than the batch size e.g. 1 litre of a 20l; in your 10l case this maybe a half a litre.

The kettle (brew pot) loss is what you lose decanting into your fermenter; this depending on your grain bags and grains would be some sediment that you wouldn't transfer to the fermenter. Naturally boiling for 80 minutes will cause loss to evaporation; +- 1 to 1.5 litre for a 10l recipe.

The sparge water is what you used to wash the mashed grains; basically you add the strike water and your grains sand let it steep at 73°C for over an hour (the mash) -- during this mash cycle the grains will swell up and absorb a lot of water i.e. the grain absorption (+- 3litres for you); the wort not absorbed by the grains is called the first runnings; what we need to do is to replace the water that was lost to absorption and factor in the boil losses, brew pot sediment losses (kettle loss), the fermenter trub loss.

The quantity of water which we add after the mash cycle is called the sparge water (taken from your strike water) and is poured over the grains to extract more of the sugars / starches that are clinging to the grains; this wort run off is referred to as the second runnings. The volume of the first and second runnings less boil loss and less trub loss should equal your brew target volume that will bee transferred to the fermenter to cool down to 22°C to then pitch your yeast.

For the strike water I have a 30l urn that I keep full and at 73°C during the mash to be used for the initially mash water i.e. 18L in the table above, and then also for the sparge water i.e. 12L in the table above to extract the second runnings from the grain. The more expensive brew kettles (pots) take water out of the tap spigot and flow through a silicon pipe to pour over the grain slowly and continuously during the mash to secure a maximum extraction of starches / sugars. Manually we achieve this either by scooping some water in the kettle with a container and slowly pouring it over the grain during the mash cycle; followed then by sparging to extract the second runnings.

Target Sugar Gravity

12 °P is gravity on the plato scale; converting this to specific gravity is 1.048. i.e. this is what your wort gravity should be after the mash and after the boiling. Naturally you can also manually bump it up by adding sugar; but you should get quite close to this just with a mash and good regular sparging, and the boil.

Hops

The Tettnang hops is expensive and can be substituted with a cheaper hops; the SAB variety is a lot more affordable. Remember the addition of hops in recipes will alwasy comprise of quantity and time; where the time represents how long before the end of the mash. In this recipe; the boiling is 80minutes long, so 10 minutes into the boil you would add the hops in your hops bag. It is quite typically to have separate bags for the grains and the hops; because the grains are removed before the boil, and the hops is added in its bag during the boil. You either buy the reusable bags, or you make you own using muslin cloth. You can also get stainless steel mesh

containers for grains and

hops additions.

Fermentation

The duration of the fermentation depends largely on the temperature, the gravity and the yeast; at 22ºC; you can expect the gravity to roughly change by about 0.005 per day. You're target for an all grain brew should be a ending gravity of 1.010 -- meaning it'll take about 8 more days to get to 1.010 from 1.050 (rounded up 1.048) -- which would give you an ABV of 5.25%.

Naturally the more sugar (higher gravity) the more active the yeast; meaning as the gravity reduces the yeast become less active and it can take slightly longer for the gravity to drop towards the end, and if they're colder then they'll also be slower. Don't however go above 22ºC because yeast that is too warm can produce a lot of phenols, which make your beer taste awful (e.g. bandaid flavour).

The WB-06 yeast should at 22ºC produce more esters; with some interesting favours -- e.g. it is fairly normal for a wheat beer brewed with WB-06 to produce a very pleasant banana flavour chemically known as

Iso-amyl acetate.

Priming sugar for carbonation

Once you've hit your end gravity target of 1.010; you are ready for bottling. Leave space at the top of your bottles for CO2 expansion; similar to how all carbonated are packaged. The duration of the carbonation is again going to depend on your yeast, and the temperature. To give them a kick, we add priming sugar to each bottle and then decant the beer into the bottles.

Calculating how much priming sugar to add is important, too little as you'll have little to no carbonation; too much and you could end up with a grenade (exploding caps). Simple divide

the calculated priming sugar by the number of bottles your fermented wort will need; add to the bottles, fill up with fermented wort (beer) leaving space for carbonation, and then cap the bottles. After 3 days; open a bottle and check if you're happy with the carbonation. If its perfect then start the pasteurisation process, otherwise if its not; then give it a few more days.

Beer's flavour profile does change over time; even though you would have killed the yeast during the pasteurisation; as for whether you drink it right after the pasteurisation or wait a few weeks is really a personal taste preference. Most of my beers I think are ready to drink after carbonation; could be that I'm just not that patient, or that my palate is not overly finessed.